Share

Pin

Tweet

Send

Share

Send

The task, in addition, was to obtain a greenhouse measuring 3 meters wide, 8 meters long, with the ability to freely move a person of average height in it, i.e. up to 1.8 meters. Therefore, I decided to make a polycarbonate greenhouse with a frame made of a metal profile of my own design.

The frame outlined mainly from a light metal pipe and corner. The design of the "roof" made ridge type, the usual gable, tested in reliability. The height of the ridge will vary depending on the weather conditions in your area, I chose with a rafter angle of 45 degrees, so that snow easily rolled in the winter. When installing the rafters reinforced with a transverse beam, connecting with a triangle.

Standard polycarbonate sheets have the following dimensions: thickness 4 mm, width 2.1, length 6 meters. I draw attention to the quality of polycarbonate, I used the Russian manufacturer Sunnex, let's say it is of medium quality, there is a more durable and dense material, this is noticeable in the deflection, structure and weight, throughput to ultraviolet. The choice is yours, but do not save, in order to avoid its breakthrough under load from snow or wind.

Traditionally, construction began with laying a small foundation, since in my case the greenhouse needed to be fixed thoroughly, as well as to avoid distortions. I applied thin foundation blocks and reinforced concrete sleepers. Bolts for powerful fastenings of the frame around the entire perimeter of the greenhouse were laid in the "regular" holes of the sleepers. During the installation of the entire frame structure welded in parts, these fasteners served as a fixing service for the further installation of the upper grille (however, assistants to support the frame were currently needed).

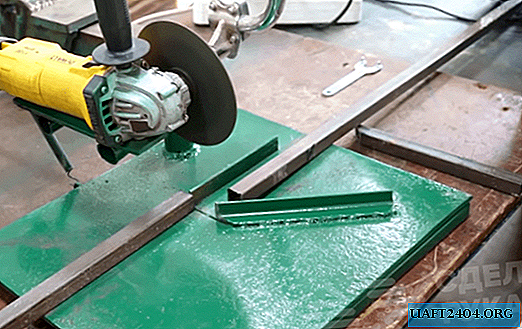

Caracas made from a metal profile pipe 20 * 40 mm with a grate up to 1 meter, otherwise polycarbonate may fall through in winter from icy snow. He made the lower ends from the corner 35 * 35 mm so that the door would close at the joint.

Not an unimportant moment, we design the frame in such a way as to cut polycarbonate most economically, namely, we make the side walls 1.05 meters high, taking into account cutting the sheet in half lengthwise. Rafters 2.1 meters long, in order to fix two sheets on the roof and cut one additional sheet into pieces of 2 meters.

In addition to the door, I provided two windows for ventilation in the greenhouse, from the lee side at the end and side of the structure, welded 20 * 20 mm from a light profile. I installed the windows on the piano hinges, they are quite thin and do not interfere with the polycarbonate to fit snugly to the frame.

All joints and holes in the polycarbonate passed through silicone, and from the bottom of the gap with mounting foam. The frame in the places of welding was sanded, painted with an anti-corrosion compound and paint.

Material for building a greenhouse:

- polycarbonate 2.1 * 6 m. - 5 sheets;

- metal profile pipe 20 * 40 mm - 120 meters;

- metal profile pipe 20 * 20 mm - 18 meters;

- self-tapping screws with a washer and a drill - 1000 pieces;

- foundation blocks (sleepers) with a total length of 22 meters;

- sand for laying the foundation;

- fasteners and bolts for the frame;

- anticorrosive paint;

- door and piano hinges, door handles;

- welding electrodes 3 kg.

Advantages of the greenhouse: gable solid construction; rigid fastening of the frame; required geometric dimensions; the convenience of use; the possibility of economical cutting of material; few joints.

Disadvantages: the junction of the roof and side frame truss turned out to be reinforced, as it were, with two profiles, which is not economically viable.

Share

Pin

Tweet

Send

Share

Send