Share

Pin

Tweet

Send

Share

Send

Its construction was simple: a transformer with two windings - a 220 V network and a winding of 2 turns of a very thick wire. And already a sting made of wire was connected to the low-voltage winding, which was heated under the influence of a strong current.

He had such a soldering iron with a number of very advantageous advantages:

- - Instant heating. 1 second and ready to go.

- - Save energy since most of the time it is turned off.

- - The sting can be bent to any shape. Say, make it rectangular and solder microcircuits in seconds without overheating.

Of course, there are drawbacks: the soldering iron is too heavy for long soldering. A poorly assembled transformer buzzes, which is sometimes annoying.

The advantages of a soldering iron are of course more substantial. I decided to buy such a soldering iron again, but there are no more in the production. Therefore, I will do it myself.

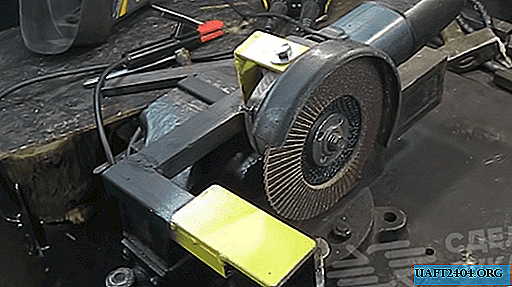

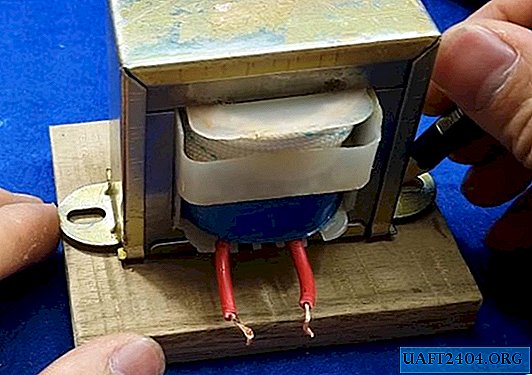

The main thing is that you need to find a 220 V transformer with any secondary winding. I tore this out of the old music center. Recommended power from 30 watts, this trekking at 40 watts.

Instant Soldering Iron Making

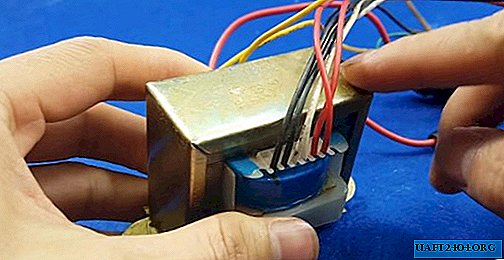

We disassemble the transformer and remove the iron casing.

Then we disassemble the core. W-shaped plates are staggered, and, in principle, are easily knocked out.

This transformer is good in that both windings are wound independently of each other.

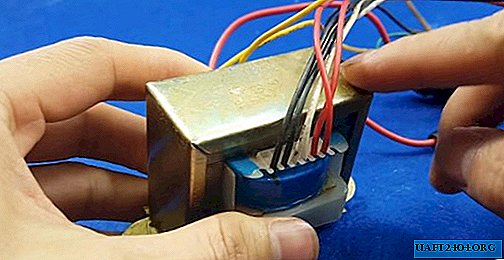

We do not touch the primary at 220 V and put it aside. We rewind the secondary winding to release the winding cage, since it will come in handy for a new winding.

We take a fiberglass insulating tube of wide diameter. If you do not have it, then you can insulate the winding with heat-resistant adhesive tape.

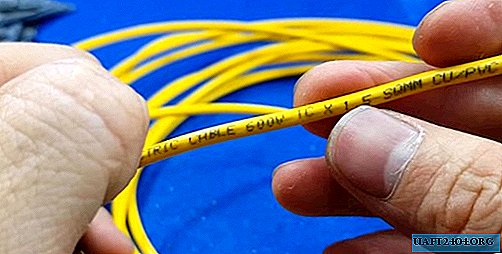

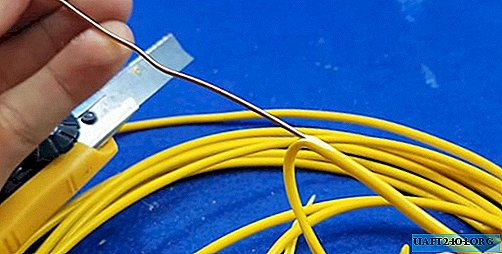

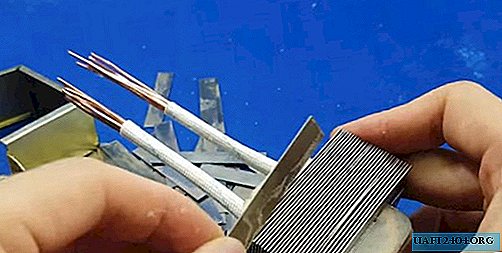

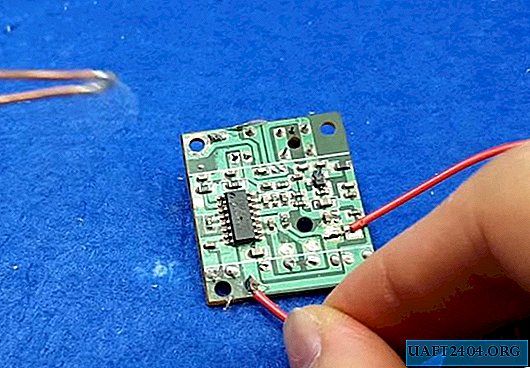

We take a single-core wire, with a diameter of one and a half squares, and clean it from insulation.

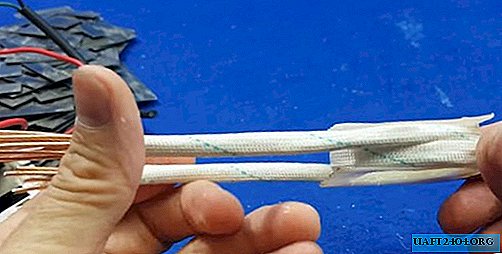

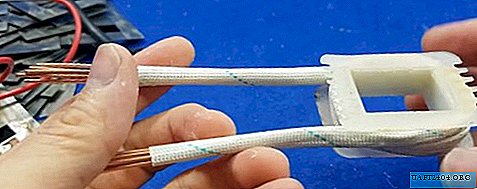

Our new winding will consist of 12 such wires, wired together. And in total there will be two turns.

We collect the wires of the wires.

We dress an insulating tube.

We make two turns on the newly released frame.

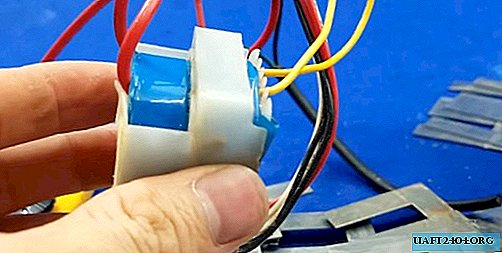

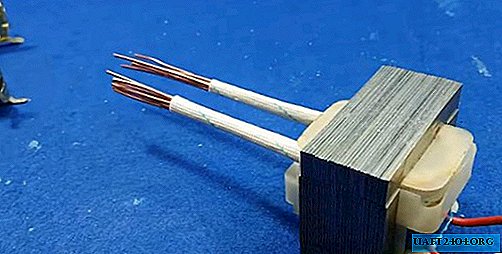

And, we collect the transformer back.

So that nothing buzzes, the sides of the core can be coated with epoxy before putting on the casing.

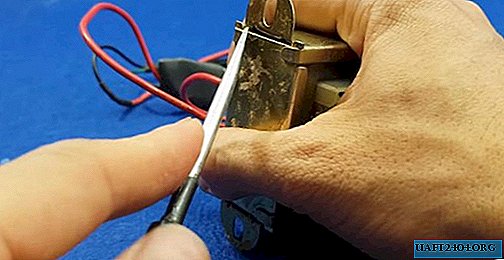

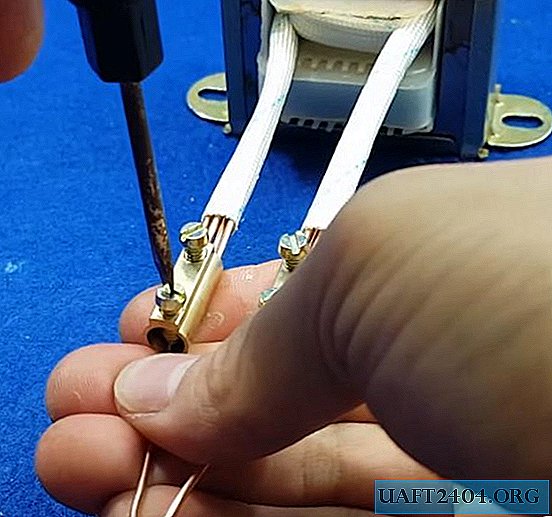

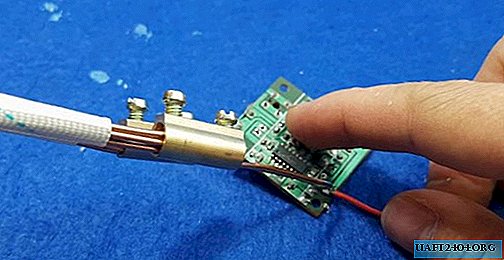

From the pads for wire connection, we will make clamps for the sting.

The sting will be from the same cracked wire.

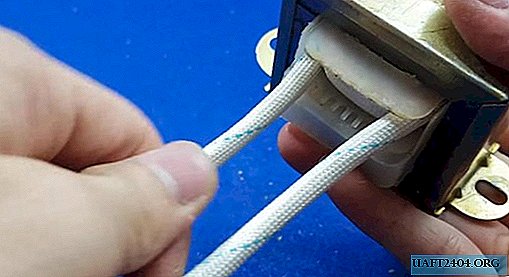

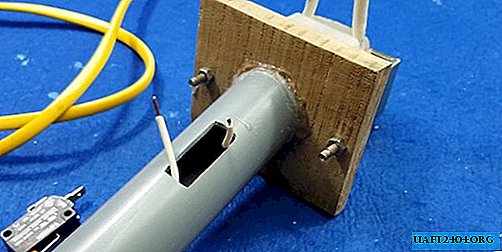

Now the case. We will put the transformer on a wooden square. From below we glue a handle made of PVC pipe.

We cut a groove under the switch in the handle. Connect all the wires.

Instant heating soldering iron is ready!

Watch the video instructions for making a soldering iron

Share

Pin

Tweet

Send

Share

Send