Share

Pin

Tweet

Send

Share

Send

Anyone who has ever soldered twists in a junction box at home knows how it feels: standing on a stool, using a soldering iron to try to solder the connection at a height. To solder the whole floor with solder is another half of the trouble, the main thing here is not to burn yourself, since it is very inconvenient to make a joint.

It is for such purposes that I recommend making a simple device, with the help of which you can quickly and very high quality make twists of twists at a height.

Will need

The design contains a minimum of parts. To build, you need to take:

- Gas burner with gas bottle.

- Stationery clip.

- Hairpin

- Four stud nuts.

- Copper tip.

Production of devices for quick soldering

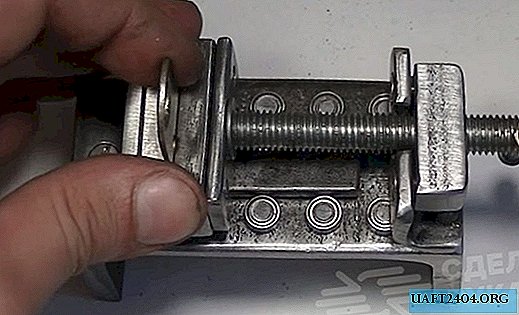

I show the finished copy and in words I will tell how to make it. Repeating it is not difficult, so you will understand everything without difficulty.

Studs are sold in stores about a meter in length, so you need to cut a 15 cm length with a hacksaw.

Next, drill a hole in the center of the stationery clip along the diameter of the stud.

Bend the hairpin at an angle of 90 degrees, for this it is convenient to use a vice. And screw on the nut at one end, put on the clamp and fix with another nut on top.

On the other end, we also screw the nut, tip, nut.

We put the device on the nozzle of the gas burner, already with an attached gas cylinder.

We light the burner and use the nuts to adjust the distance of the tip on the stud so that the flame optimally abuts the tip at a short distance. During operation, this distance can be adjusted by moving the clamp along the nozzle of the gas burner.

Solder the twist of wires

We take a liquid flux. It can be LTI-120, alcohol-rosin, or any other active flux designed for soldering non-ferrous metals.

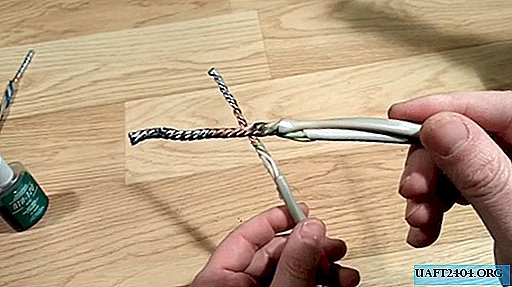

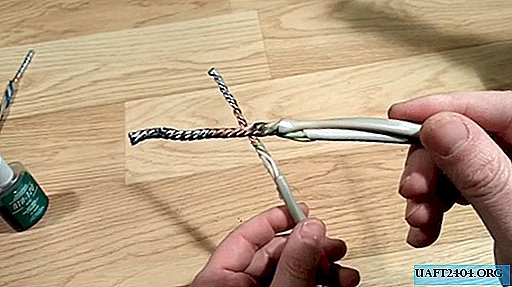

Dip the twist into it and hold it for 1-2 seconds for better penetration of liquid into the cracks between the wires.

Next, we wait for the tip to warm up and place a small amount of POS-61 type solder in it. I soldered the fixture earlier, so I only need to wait for warming up.

As the solder started to spread, dip the twist into it and wait 1-2 seconds until the connection warms up and a soldering occurs.

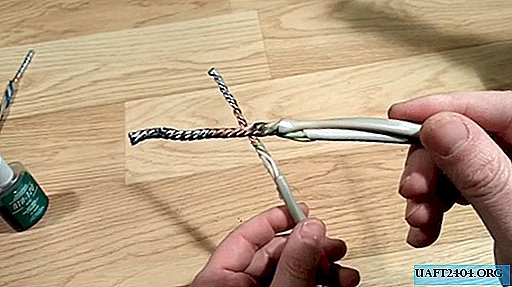

It ended up like this:

As you can see, the edges of the braid are melted. And to prevent this from happening, it is necessary to hold the twist with pliers. They will perfectly serve as a heat sink and there will be no such problem in the future.

In general, the soldering turned out to be of high quality, fast. Therefore, I recommend repeating this design and not to suffer.

At the end, turn off the burner, but do not lay down the tool. It is necessary to put or hold the entire structure vertically for 10-15 minutes until the solder cools down. Otherwise, it may spill over.

Also be careful: the tip gets very hot - do not burn yourself.

Share

Pin

Tweet

Send

Share

Send