Share

Pin

Tweet

Send

Share

Send

Many gear mechanisms consist of plastic gears, the teeth of which can wear off under load. This especially happens when the internal lubrication ends after a long period. An example of this would be a car wiper motor, an electric meat grinder, a blender, a spinning reel, etc. In the presence of a worn gear, it is not necessary to look for a replacement, since its teeth can be restored with two-component epoxy glue.

Will need

Materials and tools:

- two-component epoxy repair adhesive;

- degreaser;

- screwdriver;

- knife;

- rags.

As an epoxy adhesive, you should choose a repair composition that can be used to build up and restore fragments of parts. Information on this is indicated on the packaging. Also, the epoxy must have low shrinkage and be resistant to aggressive environments, including high temperatures.

Restore Plastic Gear

The gearmotor itself initially slips under load and even when operating without load has unpleasant noise and rattle.

First of all, you need to disassemble it and remove the broken gear from the worm gear, since it is all the fault. All available parts of the mechanism must be cleaned of grease with alcohol, solvent or gasoline. The fact is that it contains erased particles of plastic wear, so it does not work well.

Using a sharp knife, you need to remove plastic flows from a worn gear. After that, its surface must be degreased for normal bonding of epoxy glue. The remaining parts of the gearbox are not degreased.

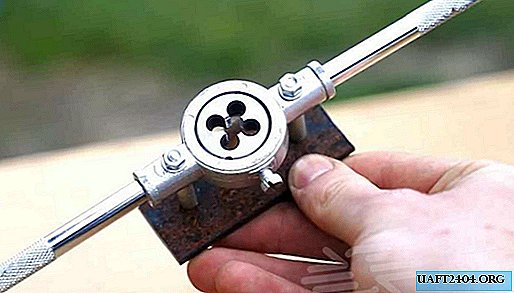

The required amount of two-component epoxy adhesive is kneaded according to the instructions. The composition is applied to the problem areas of the gear with a small exit to normal teeth. You need to wait until the glue becomes plastic, resembling plasticine. This will take 10-20 minutes, which depends on the manufacturer and the ambient temperature.

A worn gear with plastic adhesive is installed on its seat. Next, you need to start the electric motor for the mechanism to work. As a result, a whole gear or worm gear rolls the teeth on the broken part, squeezing out excess glue. Since the remaining parts of the gearbox are not grease free, the resin will not stick to them.

After a minute, the engine can be turned off and the restored gear removed. The adhesive undergoes complete polymerization in 12-24 hours. After that, the part can be put in place, cutting off excess flows.

Lubricate all gears with solid oil or lithol and assemble the gearbox in the reverse order.

If the surface was completely degreased and good glue was used, then the quality of the reconditioned gear corresponds to the new part.

Now there is no slippage, even with a strong hold. The work is quiet, without gnashing and creaking.

Share

Pin

Tweet

Send

Share

Send