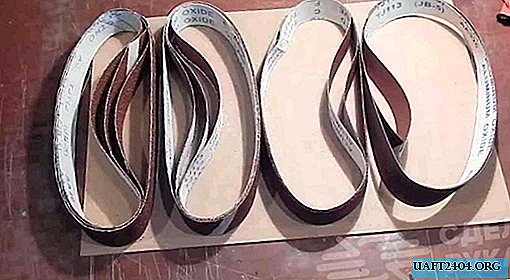

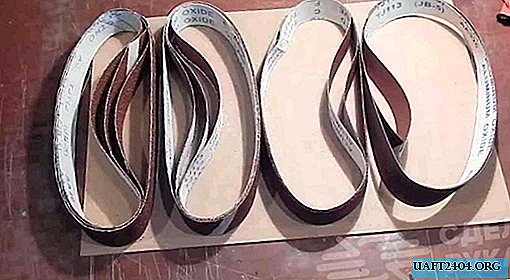

In this review, the author shows the step-by-step process of gluing a sanding belt (for a grinding machine or grinder).

This method is not only simple, but also avoids beating when using a sanding belt.

First of all, it is necessary to cut the sanding belt into pieces of the desired length, and then cut into strips of the desired width.

Using a stencil, the author cuts off the edges of the strips at a certain angle from two sides.

We recommend reading: how to make a simple belt grinder from angle grinders with your own hands.

The main stages of work

At the next stage, we bend the edges of the strips and remove the abrasive at the bend.

The back side of the strips (where there is no abrasive) will need to be saturated with white spirit. You can use an ear stick for this.

After that, we turn the strip over and remove the abrasive with a knife.

Then you can proceed directly to gluing the strips. We coat the fabric base with glue (the author uses the universal waterproof glue Moment 88) and glue the edges together.

This gluing method is perfect for sanding belts with a grain size of 40, 60 and 100.

But for gluing sanding belt 320, you must already use the backing and glue butt. Only in this case, you can avoid "discomfort" in the process.

For details on how to glue the sanding belt so that there is no beating, see the video.