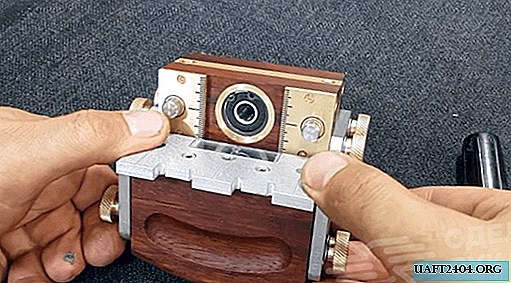

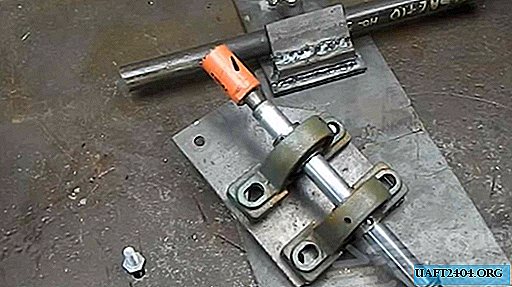

First of all, it is necessary to cut out the base of the device from a sheet of metal with a thickness of 6 mm. Moreover, the rest of the sheet is also useful - the master installs 2 case bearings on them.

In order to install case bearings, you first need to make markings, and then drill holes for the fasteners. In this case, these are bolts.

After that, the author makes a platform with an emphasis for pipes and additionally makes a clamp that will fix the workpieces.

The main stages of work

At the next stage, the author proceeds directly to the assembly of the device. A vise is attached to the base, as well as a platform with case bearings.

Please note: if the vice is fixed to the base rigidly by welding, then the platform with bearings into which the shaft is inserted must be movable.

This design makes it possible to set the crown for metal relative to the workpiece itself at different angles: at an angle of 90 and 45 degrees, which is very convenient.

To the bottom of the base, the author welds a piece of profile so that the device can be fixed in a vice. You can also use a piece of corner for this.

As a drive, you can use an electric drill or a screwdriver. But the drill, of course, will be better.

For more information on how to make a do-it-yourself device for cutting saddles in pipes, see the video on our website.