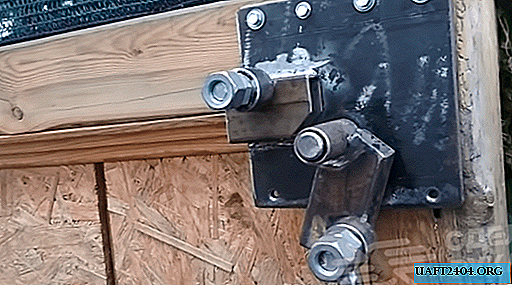

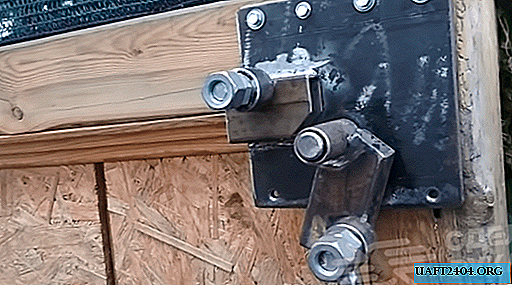

In order to make a simple machine tool yourself, you will not need to perform any complex operations (including turning), look for bearings, etc. For this, metal scraps that remained after repair or construction are quite suitable.

For this homemade product, trimming pipes of different lengths and diameters will be required. It is desirable that their wall was 3 mm. You will also need to prepare a piece of round timber with a diameter of 20 mm, a plate and rectangular profile pipes with a cross section of 25x50 mm.

Steel water pipes for the manufacture of a home-made rebar will require the following sizes (outer diameter): 33 mm, 26 mm and 21 mm. The square steel plate 7.5 mm thick has dimensions 17x17 cm.

Of the other components for the "home" version of the machine tool, M16 bolts will be required (the length of the bolts can be arbitrary - they will still be cut to size in place).

The main stages of work

A roller is made from pipe segments of different diameters, the thickness of which is about 9 mm. For this, three pieces of pipe with a diameter of 33 mm, 26 mm and 21 mm are simply inserted into each other and scalded. Therefore, it is important that their wall thickness is at least 3 mm.

In two sections of the profile pipe 25x50 mm, with the help of a grinder, cuts are made under the M16 bolts, one of which will then be put on a home-made roller. After that, a hole for a round diameter of 20 mm is drilled in a metal plate.

At the last stage of work, all the parts are interconnected by welding, and a simple rebar from metal scraps is ready for use. A detailed assembly process of the machine can be seen in the video on the site.