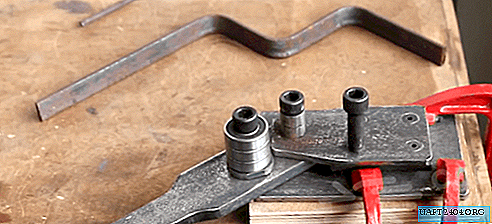

To make a DIY mini manual bending machine for metal for a home workshop or garage, you will need a minimum of materials and affordable tools. For this homemade work, it is necessary to prepare pieces of sheet metal of a suitable size, bearings and fasteners.

On a home-made bending machine for metal, you can bend steel strips at different angles, as well as round and square bars. The design of the device is quite primitive, but most importantly - inexpensive and effective.

The bending of the workpiece is very simple - the bar or strip of metal must first be installed in the landing "nest", stretching between two working rollers. Then, changing the position of the handle, bend the workpiece at the required angle.

The main stages of work

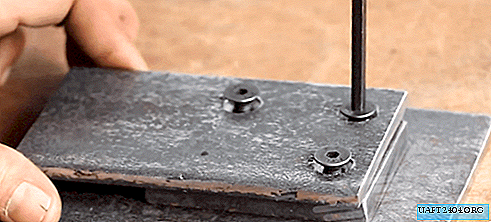

First of all, sheet metal with a thickness of 6-8 mm needs to be cut three rectangular plates of different widths and lengths. Then we carry out the marking, drill three through holes in each workpiece and connect the plates with the help of screws with a cap under the hex key.

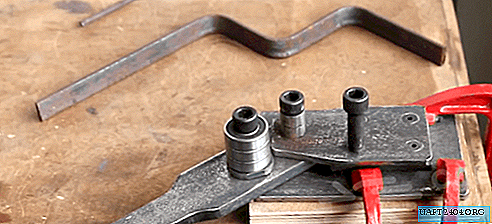

The handle of a mini-bending machine for metal is made of a long plate of the same thickness as the previous workpieces. A hole for the bearing is drilled at a distance of 1-2 cm from the edge. A bolt with two nuts is inserted into the inner race of the bearing, on which the edges must be sharpened.

Then at a distance of 5-7 cm from the bearing, another hole is drilled in the handle - a bolt is inserted into it, on which three small bearings are put on.

How to make and assemble a manual bending mini-machine for metal, see the video on the website.