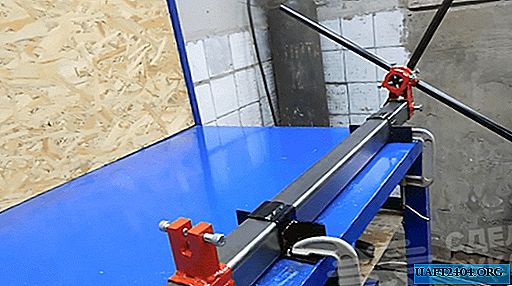

To make a home-made drilling machine that is ideal for the home workshop, profile pipes and other available materials will be required. First of all, it is necessary to make a base for the vertical stand of the machine - for this, we weld the frame from a 60x60 mm profile of a rectangular shape.

Basic welding

On top of the metal frame, we weld a steel sheet 4-6 mm thick, which must first be cut to size so that it does not protrude beyond the edges of the profile. We clean the seams with a grinder. Next, we make a vertical stand - for this we cut off a profile pipe with a wall size of 60x60 mm and a length of 65 cm.

Then we weld the vertical stand to the base. Four pieces of 8 cm long must be cut from a steel corner of 25x25 mm. After stepping away from the edges of the corners of 2 cm, we drill holes - we need to cut threads in them. We put bearings on the bolts, squeeze the nuts and screw these parts into the holes in the corners.

We prepare four plates for the size of the structure, and then compress them with clamps and weld together with the corners with bearings. Next, we weld a piece of the profile pipe to the plate.

Drilling Machine Assembly Steps

We fasten the profile pipe with the plate to the guide using bolts with caps under the hexagon. Before welding the spindle, you need to make a seat for it so that the joints are with a small gap.

The motor mount is very simple - anchor bolts with a ring are screwed to a corner of 25x25 mm, and there, to which the motor is directly attached, two bushings are welded. The pulley with the shaft can be removed from the old grinder.

At the last stage, a lifting mechanism and handles are made, which are attached to the washer by welding. All elements are painted and then collected. The result is a very cool and inexpensive do-it-yourself drilling machine.