Despite the fact that today you can buy factory clamps in a hardware store or on the market, in some cases it is more practical to use wire clips that simply twist with pliers.

However, for a quality tightening of such clamps, it is better to use a homemade device. The main advantage of the "home" tool is its convenience and compact size, and you can make it yourself from available materials.

The main stages of work

To begin with, it will be necessary to prepare two identical workpieces from a steel plate 25 cm long and 4.5 cm wide. We make the marking with a caliper and use the grinder to cut off the excess parts. Then we cut the cut points on a grinding machine or using a file for metal.

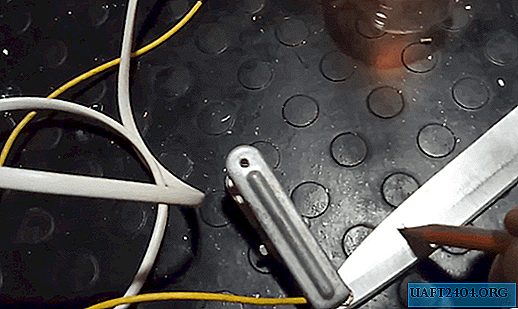

We weld one nut to the edges of the obtained blanks. After that, we drill through holes in these plates and reliably connect them using nuts and bolts of suitable sizes. At the top of the handles (on the outside), one steel pin must be welded.

Operating principle

To work with such a homemade tool is very simple. We wrap the wire around the place where you want to install the clamp, wrap its edges on metal pins on the sides of the device and squeeze the handles. The wire is tightened and then it remains only to twist (literally a couple of turns).

In this way, it is possible to fasten wire clamps quite quickly and without much effort. The detailed manufacturing process of this homemade tool can be found in a separate video on our website.