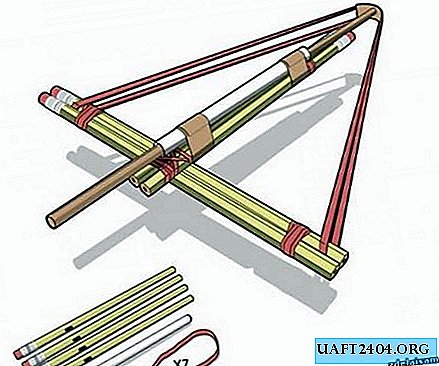

Using such a home-made clamp, it is possible to reliably fix steel pipes of various diameters for machining (cutting, grinding, etc.). The design of this device is quite simple, and the pipe clamp itself is convenient and practical to use.

Preparatory work

First of all, from a piece of steel strip 3 cm wide, it is necessary to cut four workpieces 18 cm long, in which you need to drill holes on one side.

You will also need to use a small segment of the steel square - in it you need to make five holes along the entire length, located at an equal distance from each other

Next, take a long bolt, cut off the cap, heat one end of the stud to red with a gas burner and flatten it with a sledgehammer or heavy hammer. Then in this place it is necessary to drill one through hole.

In two 18-mm-long inserts, another hole must be drilled from the opposite side to connect to the stud.

It will also be necessary to cut off two pieces of an equal-shelf corner of 5 cm length. They are welded to two plates, in which it is necessary to cut a triangular notch using a grinder. Further welding is carried out.

Clamp assembly

When all the main structural elements are ready, they need to be cleaned from rust and painted, and then assembled together using bolts with nuts of a suitable diameter. Using a home-made clamp is very convenient to process steel pipes, so this home-made is useful in any workshop.