Share

Pin

Tweet

Send

Share

Send

But they have one acoustic flaw that annoys many people - tap water, falling to the bottom, makes a loud noise. This is due to the fact that the wall thickness is only from 0.4 to 1.2 mm.

There are several ways to increase the sound absorption of stainless steel sinks. Below we will consider one of them.

Will need

Our method is based on the use of a flexible self-adhesive car soundproofing mat. Its thickness is only about three millimeters. You can, of course, use other similar material.

It is also necessary to stock up on the following materials and tools:

- medical alcohol or degreaser with similar properties;

- cloth napkins;

- paint spatula;

- large scissors or a sharp knife.

Operating procedure

We unfold the soundproofing mat and give him time to lie down and straighten up. Then carefully inspect the pasted surface and remove everything unnecessary: stickers, packaging elements, adhered specks, etc.

Sometimes on sinks there are factory soundproofing elements in the form of small strips. Remove them or stick new insulation on top of the existing one, it is necessary to take according to the circumstances.

If it is thin and holds firmly, then you can leave it, otherwise - remove it with a spatula and treat the place well with a cloth dipped in alcohol.

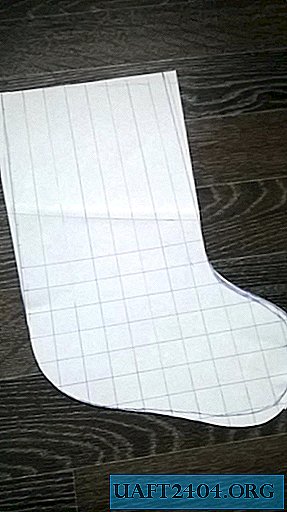

Now we take the necessary measurements on the sink, transfer them to a soundproofing mat and trim with powerful scissors or a sharp knife.

You can do at this stage and in a different way. First, we perform a paper pattern, put it on the mat and trim according to the pattern.

With any method of cutting a rug, one should take into account how and where the available brackets or other fastening elements are intended for mounting the sink.

Now we make the final cleaning and degreasing with alcohol or a substance similar in properties to the surface of the sink to be glued with sound-absorbing material.

Remove the substrate from the cut mat and gently glue it in place on the sink. After making sure that the mat is glued correctly, we press it to the surface to be glued using a paint roller or some other similar object.

Analysis

A legitimate question arises: what significantly reduced the noise from a stream of water falling into the sink? Is it really just the factor of its absorption by the mat material? Of course not. He also increased the stiffness of the bottom of the shell, and it remains to be seen which of these two factors contributed a lot to the overall result.

Original article in English

Share

Pin

Tweet

Send

Share

Send