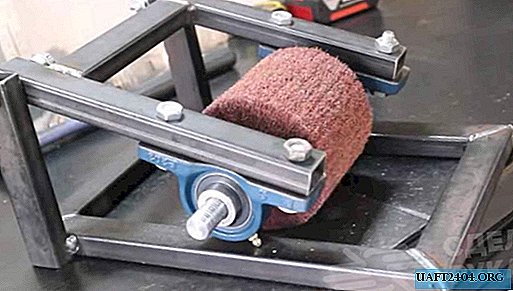

It is possible to clean rust from metal (profile pipes, plates, strips, etc.) from various methods. Someone does this with a grinder and a flap wheel. Others use an electric drill with a suitable nozzle.

But when it comes to processing long workpieces, it is better to use a simple home-made machine for this. With such an “assistant”, cleaning metal from rust will take much less time.

First of all, the master cuts four blanks from the profile pipe, cuts the corners and welds a rectangular frame from them. First you need to put the tack, and check the right angle with the diagonal. And then only you can weld.

The main stages of work

Then the master cuts off three more pieces of the profile pipe, and welds a U-shaped part from them. More, of course, is similar to the letter "H", but only with trimmed upper edges.

In the next step, you will need to grind a stud of a suitable diameter on a lathe. A drum with an abrasive is put on the axis. To install the shaft, the master uses case bearings.

Further, from the prepared parts, it will be necessary to assemble the main part of the machine structure together with the drum. And for this, the master drills holes in the profile pipes, and then connects it with bolts to nuts.

Then the final assembly of the machine and the installation of the drive are performed - in this case, the master uses a power drill. For details on how to make a machine for cleaning metal blanks from rust and paint with your own hands, see the video on the website.