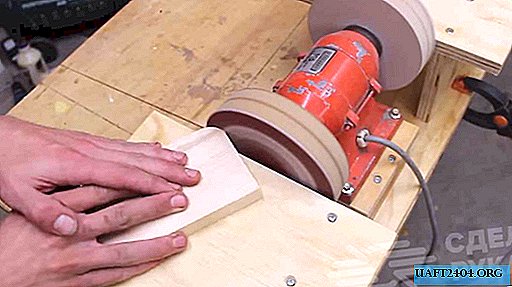

Imagine this situation: you need to weld large rectangular frames from a profile pipe in the country or in the garage, but there is no suitable table for the size of it, on which all this can be done.

In this situation, you have to perform welding on the ground. To facilitate your work: do not lay bricks or boards under the profile pipes, and also do not "catch" a right angle, you can use homemade appliances.

You can make them from a corner and a metal strip. To weld a rectangular frame, four such fixtures are required.

To make one fixture, you will need two pieces of a corner 15 cm long and a piece of a strip 16 cm long.

The main stages of work

First, cut off two pieces of the corner. One side on each workpiece must be cut off at an angle of 45 degrees.

Then we cut off a piece of metal strip - also at 45 degrees, but already on both sides.

Next, we weld together two corners at an angle of 90 degrees, and a strip is already welded to them.

At the corners of the welded part, it will be necessary to weld one elongated nut.

We screw the bolts into the nuts, and the homemade product is ready. The bolts in this case play the role of legs that can be adjusted in height.

You can see the detailed manufacturing process of this device in the video on the website.