So that when joining round steel pipes, the welds are neat and durable, you must evenly cut the saddle. At home, a radius sampling in a steel pipe can be done using a grinder, but it will take a lot of time, and the result does not always turn out to be ideal.

To do this, it is better to use a device for cutting saddles at the ends of round pipes. Using this tool, you can qualitatively prepare the end of the pipe for welding at a certain angle. Since factory models are expensive, the best option would be to make this device with your own hands.

The main stages of work

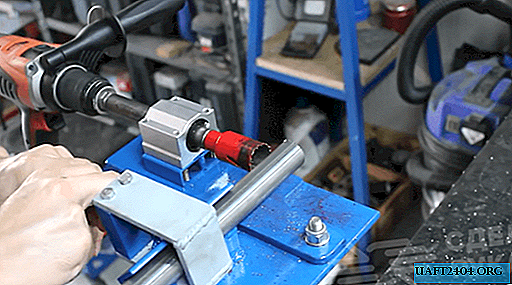

As the base, a steel plate with a thickness of 6-7 mm is used. A second plate is attached to it, which is rotary. For fasteners, bolts with nuts are quite suitable. A self-made clamp for rigidly fixing round pipes (this is a vice with a clamp), which is attached to the base, is also separately manufactured.

Two sections of the profile pipe are welded to the rotary plate, on which a bearing assembly with needle bearings is mounted. If such a unit is not at hand, you can use two guide bushings from the pillars of the car instead.

Another important structural element is the working shaft. One end of the rod will need to be machined under an electric drill cartridge, at the other - to make a landing "nest" under the crown shaft for metal. Please note that the stem and pivot plate must be parallel to each other.

The detailed process of manufacturing and assembling a homemade device for cutting saddles at the ends of round pipes can be seen in the video on the website.