Share

Pin

Tweet

Send

Share

Send

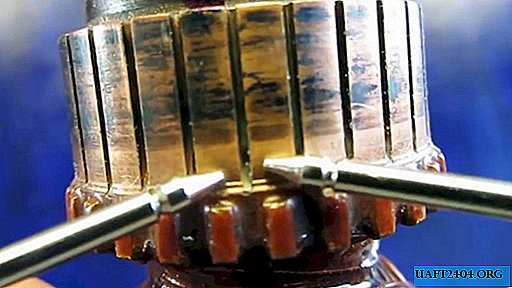

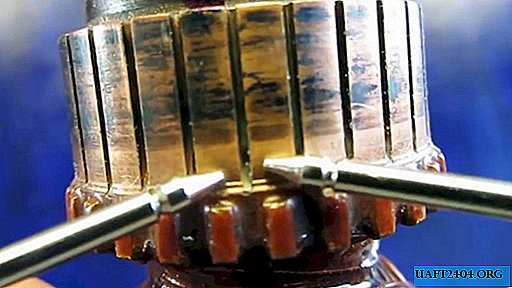

The electric motor consists of two parts: a stator and a rotor. The rotor (it is also called the anchor) is the most complex part. It consists of a shaft with a magnetic circuit in which the winding is laid. The ends of the winding are connected to the plates (lamellas) of the collector.

We proceed to the diagnosis. The main device that we will need is a multimeter.

To begin, we will analyze the electric motor and remove the anchor. It is necessary to examine it. Often, winding damage is visible to the naked eye. If the wire breakage and the short circuit are not visible, we conduct three tests.

1. 180 degree test

- We set the multimeter in the resistance measurement mode, the measurement limit is 200 Ohms.

- The probes are connected to two exactly opposite collector contacts. These two points are 180 degrees apart.

- We measure the resistance. We remember or write.

- Next, we measure in a circle between the other opposing plates.

To summarize. The resistance values themselves are not interesting to us. The main thing is that they be the same. That is, if the multimeter during the first measurement showed, for example, a value of 1.5 Ohms, then between the other opposite plates there should be the same resistance. If the resistance between some points is greater than ̶̶, then there is an open in this winding. If the resistance, on the contrary, is less than ̶̶ a short circuit.

The graph clearly tracks the internal circuit in one of the windings.

2. Testing neighboring contacts

- The device remains in the same position - resistance measurement, limit 200 Ohms.

- The multimeter probes are connected to two adjacent collector plates.

- We make a measurement, remember the result.

- Next, we measure between the next pair of contacts. And so on, in a circle.

- Compare the results.

In this test, as in the previous one, the main thing is the equality of values. And, as in the previous test, an increase in resistance means a break in the winding wire, and a decrease in resistance means a short circuit.

The graph shows an internally interturn circuit in one of the windings.

3. Check for short to housing

- The multimeter is set to a resistance measurement mode of ̶̶ 200 Ohms.

- We put one probe of the device on the collector plate, the second on the armature body (shaft or magnetic circuit).

- Alternately, we measure between each lamella and the body.

If the multimeter shows “1” ̶̶ there is no short to the case. If it shows any values, or "0" and emits a sound signal, then the insulation is broken.

Validation Results

The motor anchor is operational if:

1. The resistance between all opposite contacts is equal.

2. The resistance between all adjacent contacts is equal.

3. The resistance between the collector plates and the housing is infinity "1".

Recommendations

Electronic multimeters, especially for domestic use, have some margin of error. Therefore, it is better to use a pointer device. If there is none, it is desirable to determine and take into account the measurement error. This is done as follows:

- in the resistance measurement mode, with a limit of 200 Ohms, we connect the probes together;

- if the instrument readings are “zero” ̶̶ there is no error;

- if instead of zero any other digit, this will be an error.

Let's say the multimeter showed 0.1 ohms. Therefore, in the first and second tests, the resistance difference of less than 0.1 ohms is not considered damage.

Safety precautions

When checking the rotor, the following safety measures must be observed:

- disconnect the electric motor from the mains before disassembling;

- The damaged anchor may have sharp edges, torn collector plates or stick out damaged wires, so work gloves must be used.

Share

Pin

Tweet

Send

Share

Send