For an electric drill and screwdriver, you can make a do-it-yourself grinding nozzle of a drum type with two bearings. With the help of this simple homemade nozzle, it is very convenient to grind the ends of parts and workpieces from wood, as well as make radius recesses.

The presence of two bearings, which are mounted on the end of the nozzle shaft, provides better grinding of parts. You can make a homemade drum nozzle for grinding work from available materials. You will need a pair of bearings, two nuts, a steel rod with a thread on the end, and round plywood rounds.

The main stages of work

First of all, we screw a nut on the threaded part of the steel rod, then we put on two bearings and fix it with a second nut. Then, using a crown on a tree, we drill five round blanks from plywood.

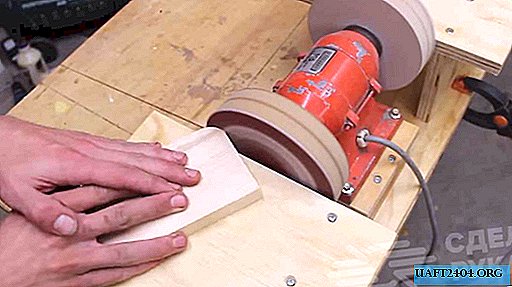

At the next stage, we put five rounds of plywood on the shaft (previously it must be greased with two-component glue), and fix it with a nut. Then we grind the wooden rollers so that their surface is even and smooth.

On a circular saw, we make a longitudinal cut in the workpiece. Then cut off the sandpaper of the desired length, put on the drum and fix on the sides with two small screws. As a result, we get a ready-made nozzle for an electric drill or screwdriver.

With one hand we hold an electric drill or screwdriver, with the other - bearings. And thus it is very convenient to process wooden workpieces.

The detailed process of manufacturing a drum grinding nozzle with bearings, see the video on the website.