The compact two-tier welding trolley for a semiautomatic device, made by hand from improvised materials, will allow you to transport a welding machine in your home workshop or other room, as well as a cylinder along with hoses and gearboxes. Thus, you can quickly organize a workplace.

Of the basic materials for the manufacture of a makeshift trolley for transportation of the welding machine, trimming of the profile pipe, two pieces of steel expanded metal mesh with diamond-shaped cells, two legs of the old metal chair and castors are required.

The main stages of work

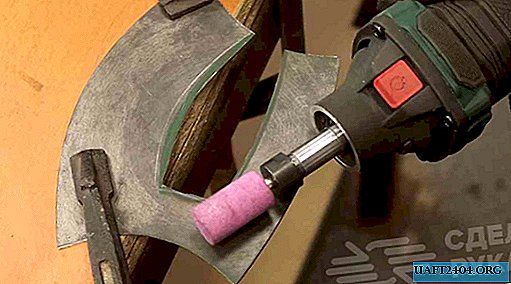

First of all, we disassemble the metal frame of the chair - for the manufacture of the trolley you will need two U-shaped legs, as well as two tubes bent by the letter “G” which are used as the backrest of the chair. Cut off the necessary parts with a grinder.

Of the four sections of the profile pipe with side dimensions of 20x20 mm, the frame for steel mesh is welded. The legs of the chair are welded together at a right angle. Then it is necessary to weld two L-shaped tubes, and on top put a metal frame with expanded metal mesh, rigidly fixing it by welding.

For greater reliability, stiffeners and jibs are welded. At the last stage of work, a lower platform for a gas cylinder is made and the castors are welded. The welding spots must be cleaned with a grinder, and the surface painted. The manufacturing process of the trolley for transporting the welding machine, see the video on the site.